What Are Crate Engines

Let’s look at crate engines, their advantages, disadvantages, and how they’re changing the landscape of automotive modification and performance enhancement. If you’re an auto enthusiast or a gearhead looking to improve the performance of your vehicle, you’ve come to the perfect place.

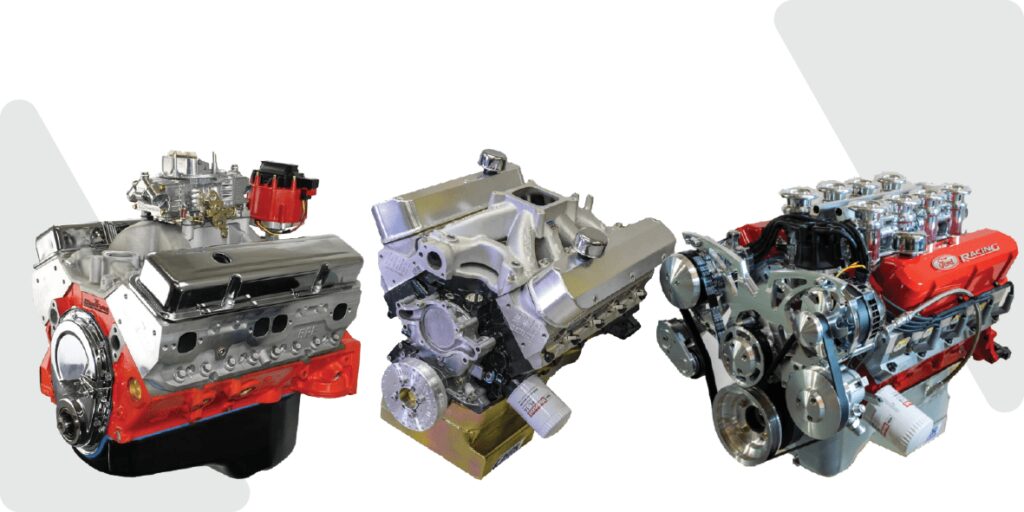

Crate engines, sometimes known as “turnkey engines,” are pre-assembled, ready-to-install powerhouses that provide a significant improvement over stock engines. These engines are carefully designed by professional engineers.

They are available in a variety of configurations to suit a variety of applications.

What is the difference between a crate engine and a manufacturer engine?

A crate engine and a manufacturer engine are both automotive engine terminology that refers to significantly different items.

A manufacturer engine is the engine that comes standard with a new vehicle from the manufacturer, whereas a crate engine is a standalone engine that may be purchased separately for custom applications or replacements.

A manufacturer engine, often known as an OEM engine (Original Equipment Manufacturer), is the engine that comes pre-installed in a vehicle when it is first manufactured by a car manufacturer.

This engine is designed, manufactured, and calibrated by the vehicle’s original manufacturer, whether it’s Ford, Audi, Toyota, Chevrolet, or another car manufacturer.

Manufacturer engines are designed to fulfill the manufacturer’s performance, efficiency, emissions, and reliability specifications. They are typically mass-produced and designed to fit a diverse range of cars within a single model or series.

The main difference between a crate engine and a manufacturer engine is one of context and intent.

In contrast, a crate engine is a completely constructed engine that is sold separately by manufacturers or aftermarket providers.

It’s essentially a readymade engine that can be ordered for installation into a vehicle by individuals, car enthusiasts, mechanics, or custom car builders.

Crate engines provide the benefit of ease and performance because they are frequently tweaked or constructed for specialized applications such as high-performance, racing, or even antique automobile restorations.

They enable engine swaps and improvements without the need to replace an existing engine.

What comes with a new crate engine?

When you buy a new crate engine, it usually comes with a number of components and features to guarantee that you have a fully functional engine package.

The particular contents will vary depending on the supplier, the type of engine, and any customization options you select, but the following are the main components that are commonly included with a new crate engine:

- Engine block and internals: The engine block, which includes the cylinders, pistons, crankshaft, connecting rods, and other internal components, is the heart of the crate engine. For best performance, these components are frequently pre-assembled and balanced.

- Cylinder heads are typically included and may arrive fully completed with valves, valve springs, and other necessary hardware.

- Camshaft and valvetrain: The crate engine may include a camshaft and valvetrain components such as lifters, pushrods, rocker arms, and, in some cases, a timing chain or belt.

- Intake manifold: Depending on the crate engine, a stock or aftermarket intake manifold may be included. The air-fuel mixture is delivered to the cylinders through an intake manifold.

- Exhaust manifolds vs. headers: Some crate engines may come with stock exhaust manifolds, but others may come with performance headers. Exhaust Manifolds are in charge of removing exhaust gases from the engine.

The majority of trustworthy suppliers of crate engines offer documentation that includes installation guidelines, warranty information, and any essential technical data.

- Oil pan: The oil pan holds the engine’s oil, and the oil pump guarantees adequate lubrication. A crate engine kit will typically include these components.

- Distributor or ignition system: Depending on the engine type, a crate engine may include a distributor, ignition coils, spark plugs, and other ignition-related components.

- Fuel injection system vs. carburetor: Some crate engines are made to function with fuel injection systems, while others are made to work with carburetors. It’s possible to include the necessary parts for the gasoline delivery system of choice.

- Harmonic balancer and accessories: A harmonic balancer reduces engine vibrations, and pulleys, belts, and brackets may be standard or optional accessories that are also available.

- Gaskets and hardware: To ensure a leak-free and secure installation, gaskets and essential hardware (bolts, nuts, etc.) are frequently included when assembling the engine.

Why are crate engines expensive?

Crate engines can be expensive for several reasons:

- Quality and performance: Many crate engines are designed and engineered to be highly reliable. To maintain the engine’s longevity and power output, high-quality components, precision machining, and meticulous assembly are frequently used. The increased attention to detail and quality control might raise manufacturing costs.

- Customization: Some crate engines are built for specific applications or performance levels, and may include features such as forged internals, high-performance camshafts, and ported cylinder heads. Customization increases production complexity and frequently necessitates specialist components, which can add to higher costs.

- Research and development: Developing a crate engine that performs well, meets emissions standards, and is reliable requires significant research, engineering, and testing. The costs associated with designing and refining these engines are often factored into their pricing.

- Branding and reputation: Reputable manufacturers with a history of producing high-quality engines and components often charge a premium for their crate engines. Customers are willing to pay extra for the assurance of reliability and performance from a trusted brand.

- Limited production: Crate engines are usually produced in smaller quantities compared to mass-produced OEM engines. This can lead to higher manufacturing costs per unit due to economies of scale. Some crate engines incorporate aftermarket components such as high-performance camshafts, pistons, and cylinder heads, which can raise the overall cost.

Manufacturers set their prices based on the perceived value of their products and the willingness of their target market to pay.

Warranty and support: Reputable crate engine manufacturers frequently include warranties and customer support, which adds value but also raises the entire cost.

Packaging and delivery: Crate engines must be properly wrapped to avoid damage during delivery. When compared to smaller automotive components, the weight and bulk of large packages can result in greater transportation expenses.

High-performance and speciality crate engines are frequently marketed to enthusiasts, racers, and custom builders ready to pay a premium for the performance they provide. Manufacturers set their prices based on the perceived value of their products and the willingness of their target market to pay.

Overall, the price of a crate engine reflects the quality, performance, customization, and support it provides. When selecting a crate engine, consumers should carefully examine their goals and budget, as well as investigate numerous vendors to get the ideal combination of value and performance.

What Are Crate Engines - Are they worth it?

Deciding if a crate engine is worth it really depends on what you’re looking for. Let’s break it down:

Performance Boost: If you’re aiming for some serious power upgrades, for racing or off-roading, a crate engine can be a game-changer. They’re designed to give you more horsepower and torque than stock engines.

Custom Projects: Got a classic car or a DIY project? Upgrading with a crate engine can be a smart move. It brings better performance and reliability, and can match up well with modern parts.

Replacing an Engine: If your current engine is toast, a crate engine can be a lifesaver. No need to rebuild from scratch – just swap it out and you’re good to go.

Time and Know-How: Building an engine from scratch takes tons of time and expertise. If you’re short on either, a crate engine is like a shortcut to better performance without all the work.

Warranty Confidence: Reputable crate engine makers often offer warranties and support. This is gold if anything goes haywire, especially with high-performance engines.

Boosting Resale Value: Depending on what you’ve got, upgrading with a crate engine might boost your ride’s value, especially in the eyes of fellow car enthusiasts.

Cost Considerations: Crate engines can be upfront pricey. But if you think long-term, they might actually save you money compared to building a custom engine from scratch.

Make sure you're picking a crate engine from a trusted maker. Good track record means you're more likely to get something that actually rocks.

On the flip side, here are a few reasons why a crate engine might not be your best bet:

Budget Tug-of-War: If your wallet’s on the slim side, a crate engine might not be the most wallet-friendly choice. Make sure it fits your budget.

Compatibility Puzzle: Ensure the crate engine works with your vehicle’s other parts, like the transmission and exhaust. Tinkering might pile on more costs.

DIY Passion: If you love wrenching and have the skills, building an engine piece by piece might be your jam, and might as well bypass the crate engine.

Restoration: For classic car buffs aiming for the original feel, an OEM engine might fit better.

Ultimately, whether a crate engine is worth it comes down to your specific needs and priorities.

If increased performance, convenience, and peace of mind align with your goals and budget, a crate engine could be a valuable investment.

However, thorough research, understanding your vehicle and its requirements, and considering the long-term benefits are important steps in making an informed decision.

Top picks

Are Turbo Engines Reliable

Are Turbo Engines Reliable? – Find out everything about Turbocharged engines.